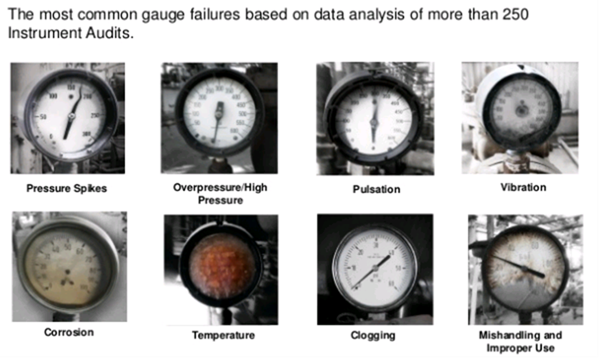

Reasons Why Gauges Fail

1. Vibration.

1. Vibration.

Many pieces of equipment vibrate. However, excessive vibration can lead to gauge failure and may indicate a problem with a component. Solution: install a gauge that will resist vibration better — i.e., a liquid-filled or direct-drive gauge with only a single moving part.

2. Pulsation.

A rapidly cycling medium within a pressure system can make a gauge pointer move erratically and eventually can lead to breakdown of internal parts. Solution: install a restrictor and liquid-filled case to dampen pulses on a standard gauge or replace with a direct-drive gauge that lacks gears and linkages.

3. Temperature.

Extreme temperatures cause sweating and loosening in metal joints and eventually can cause them to crack. Solution: install a gauge with a fully welded diaphragm seal and consider adding an on-board cooling element to combat the highest temperatures.

4. Overpressure and pressure spikes.

Frequent pegging against the stop pin can bend the gauge pointer and compromise the integrity of the Bourdon tube or sensing element and, ultimately, lead to rupture. Solution: install an overpressure protector to inhibit readings that exceed gauge capacity.

5. Corrosion.

The highly corrosive media often found in process plants can damage the sensing material in gauges. Solution: install a diaphragm seal that's constructed from material that will withstand the corrosive.

6. Clogging.

When the gauge needle is stuck in a position. A medium that contains suspended particles or is viscous or can crystallize can clog the pressure system and make gauge readings unreliable. Sediment or rust particles or moisture in the line as well. Solution: install a filter or diaphragm seal with a clog-preventing barrier.

7. Steam.

Some media produce steam or other vapors that can damage the internal parts of gauges. Solution: install either a mini-siphon loop with an internal chamber to reduce surges or a full siphon, making sure to include a coil for horizontal applications and a pigtail for vertical ones.

8. Mishandling and abuse.

Even properly installed gauges will start to malfunction if mistreated over time. Solution: conduct regular safety and maintenance training for all employees who come into contact with or proximity to gauges.