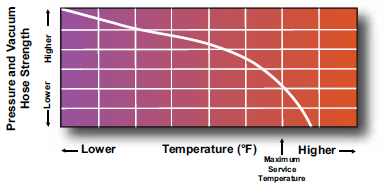

Working Pressure: The maximum allowable working pressure assigned to a hose product is based on the hose in a laboratory environment, in new condition, a straight length and at 20°C or 68°F. Hoses produced by Rubber Manufacturers Association (RMA) standards ensure the hose is built with a basic safety factor. Do not operate a hose assembly over its rated working pressure. An assembly rated working pressure is the working pressure of the lowest component (usually the fitting or clamp). It is very important to note that as operating or environment temperatures increase, the rated working pressure of the hose or assembly can rapidly decrease.

Temperature Derating Factors: System temperature is affected by both the media  and the environment. As temperatures go up, maximum rated working pressures of the hose, fitting, or clamp can rapidly diminish. As an example, a 300psi air hose assembly (see “all other” line) with ground joint couplings that is running at 200 deg/f must be derated at x.42, which puts the maximum rated pressure (including surges) at 126 psi.

and the environment. As temperatures go up, maximum rated working pressures of the hose, fitting, or clamp can rapidly diminish. As an example, a 300psi air hose assembly (see “all other” line) with ground joint couplings that is running at 200 deg/f must be derated at x.42, which puts the maximum rated pressure (including surges) at 126 psi.

Electrical Grounding: Static wires or a wire helix can prevent static electricity from building up to the point where it can arc at the assembly connection point. This static build up is created from the friction generated by the fast moving products being conveyed. In order for a hose to provide electrical continuity, the wire must properly contact the hose fittings.

Safety Factor: All hose has a minimum burst point or a safety factor. As an example, an air hose with a 100psi working pressure and a 4:1 safety factor has a minimum burst of 400psi, or 4 times the working pressure. However, the working pressure and safety factor of an assembly can be significantly altered if incorrect fittings or clamps are used. Common safety factors are: Air & Multiple Purpose Hose - 4:1; Petroleum & Chemical - 4:1; Water Hose - 3:1 -, Steam Hose 10: 1. Contact us for information on other types of hoses.

Suction & Vacuum: The term Suction generally is used with liquids and materials. The term Vacuum generally is used with air under partial vacuum. Vacuum hose does not require the heavy construction of suction hose because the dry materials or air being conveyed is much lighter than liquids or solids.

Testing & Certification: Hoses that will be used in critical applications and require fail safe service should be fully certified prior to service and at regular intervals for the life of the hose. Depending on the application, the certification process is quite involved and requires more than a simple hydrostatic test. Petroleum, steam, chemical, fire, and marine hoses are several hoses that are typically tested and should be done by qualified, trained personnel only.